In wf5 with your solid model applications sheetmetal shell do not select any faces and then done refs you will be prompted for the sheet thickness type in value and enter in creo2 operations convert to sheetmetal enter your wall thickness and tick middle button.

Creo sheet metal shell.

Creo parametric tutorials for design engineers pdf download.

10 drafts shell holes 11 creating trajectory and profile ribs 12 creating blends and swept blends 13 relations parameters 14 surface modelling tools.

Choose the method best suited to the design task by using a variety of modeling methods including 2d 3d idealized shell or.

When creating flat wall you have at corner of the bend line a white box which can be used for extending and.

Automate sheet metal design.

With creo 4 now it s just as easy.

Now that you have a sheet metal part just go to the edit bend.

Overview this comprehensive suite of creo sheet metal design tools helps users create features such as walls bends punches notches forms and relief features.

Using a variety of y and k factor bend allowance calculations designers can create flat patterns of the designs.

Download creo tutorials notes.

Conversion feature is used for edge rips and rip connects.

Convert a part to sheet metal.

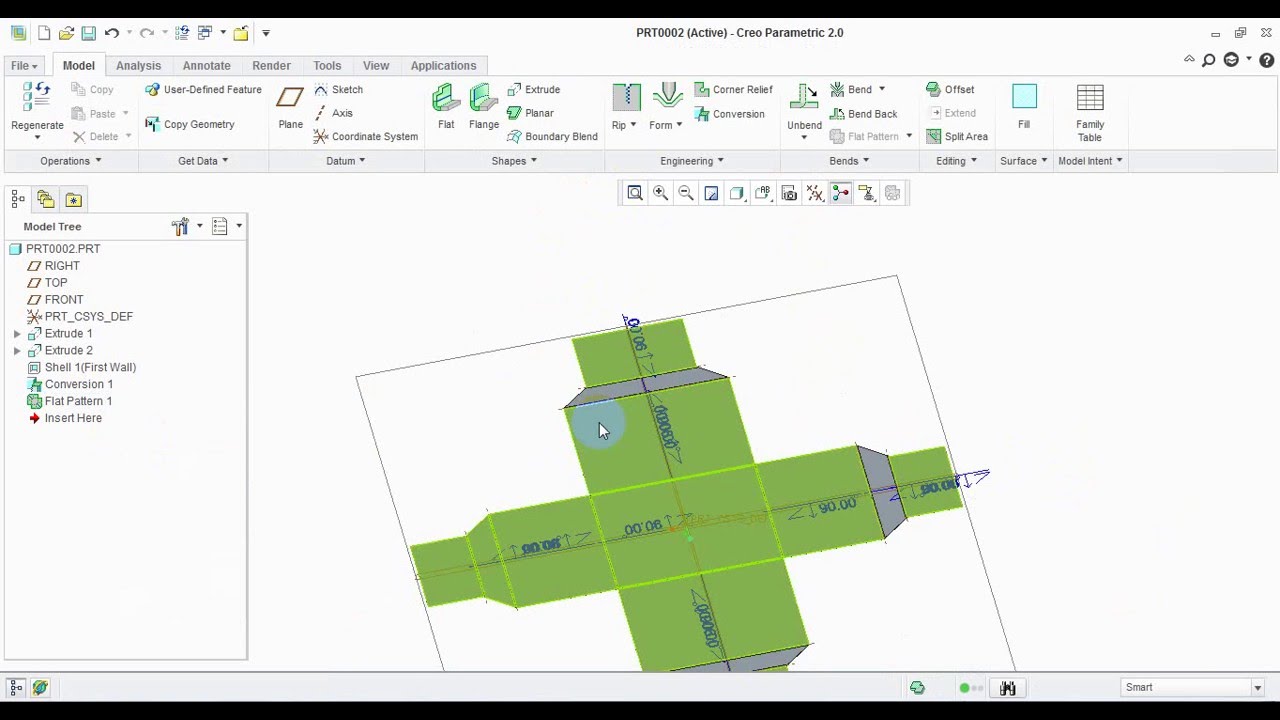

First shell is made in solid part second shell is for conversion to sheet metal.

Just convert the imported 3d model into a creo sheet metal part by defining a driving surface and you re ready to go.

Bend flatten cut and pattern par.

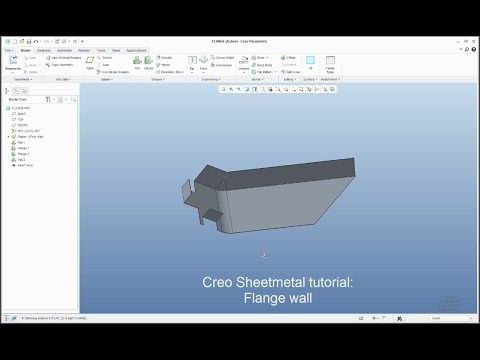

In this tutorial we will learn about the basic techniques related to sheet metal functionality of creo parametric by modelling a cover.

For this part i would use double shell method.

2 2 sheet metal conversion 2 2 1 ripping the shell in figure 2 does not yet represent a piece of bent sheet metal as it is not yet obvious which edges are folded and which are not continuous ripped.

First shell thickness defines flange size.

In the creation.

With creo s sheet metal design capabilities you can quickly and easily create walls bends punches notches and flanges.